100 anos de espírito de desenvolvimento

A MAHLE mantém as pessoas em movimento há 100 anos

O ano é 1920. Os loucos anos 20 estão apenas começando. É o início de uma década emocionante em que Charles Lindbergh cruzará o Atlântico, Albert Einstein receberá o Prêmio Nobel, Mahatma Gandhi iniciará seu protesto não violento, a Deutsche Luft Hansa AG será fundada e o Nürburgring será inaugurado. E em Bad Cannstatt / Alemanha, está sendo lançada a base para uma empresa global: nas décadas seguintes, Ernst e Hermann Mahle desenvolverão produtos que se tornarão best-sellers e estabelecerão a reputação da empresa global de hoje como inovadora.

Desde então, a MAHLE se tornou um dos 20 maiores fornecedores automotivos do mundo, com cerca de 72.000 funcionários. Hoje, somos pioneiros na mobilidade eficiente de amanhã. Nossas soluções inovadoras continuam a definir novos padrões no campo de acionamentos alternativos e na otimização de motores de combustão interna.

Qual é a nossa motivação? Queremos que as pessoas vão de A a B com eficiência e conforto. Junto com a indústria, a política e a sociedade, trabalhamos os grandes desafios do nosso tempo, sempre de olho neles. Somos os criadores da mobilidade individual sustentável. Além disso, por pertencer a fundação MAHLE, assumimos responsabilidade social.

Hoje e amanhã. Para as gerações futuras. E pelos próximos 100 anos.

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

You also want to study

the years between the milestones?

MAHLE chronicle

MAHLE Greatest Hits

A MAHLE molda a mobilidade há 100 anos. Na série MAHLE Greatest Hits, as inovações mais aclamadas da MAHLE do passado e do presente contam suas próprias histórias sobre como promoveram a mobilidade. Em seguida, também daremos uma olhada no futuro, como as futuras inovações da MAHLE contribuirão em nossa busca para moldar o futuro da mobilidade.

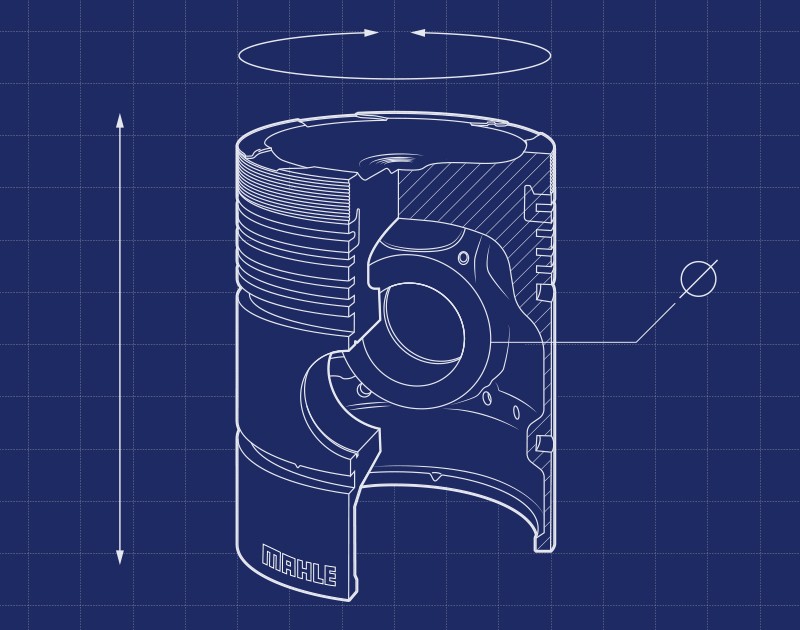

Pistão com Porta Anel

“Eu fui a chave do sucesso da MAHLE”

“A história de sucesso de 100 anos da MAHLE tem origem em mim! Pesquisa meticulosa e força inovadora têm sido elementos permanentes na MAHLE desde 1920. Os pistões eram o negócio principal da empresa – e eu, o pistão com porta-anel, fui o primeiro best-seller da MAHLE!

Meu inventor, Ernst Mahle, foi um grande pioneiro. Ele garantiu que eu melhorasse a vedação dos motores diesel e, assim, reduzisse o desgaste a que estavam expostos. Esse foi o avanço crucial que prolongou significativamente a vida útil de um motor. Não demorou muito para que eu pudesse ser encontrado em todas as estradas do mundo!

Como a MAHLE sempre impulsionou a mobilidade do futuro, eu também continuei me desenvolvendo. Nunca fui tão resiliente como sou hoje. Você pode me encontrar em carros antigos – e agora também me verá saindo das impressoras 3D da MAHLE! Seu conhecimento sobre mim também ajuda a MAHLE a desenvolver novos produtos, como soluções para acionamentos alternativos."

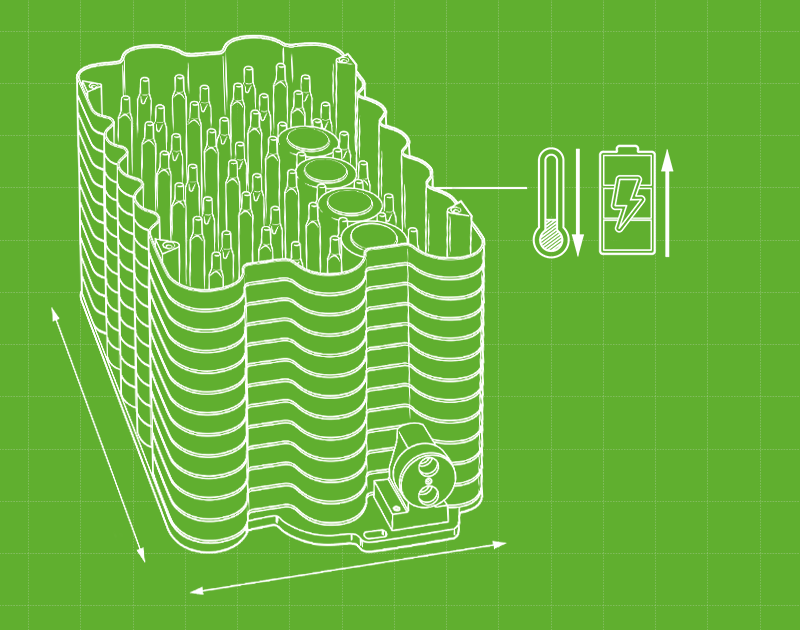

Refrigeração de Baterias

“Eu protejo baterias de vários fabricantes de veículos em todo o mundo”

As baterias são uma das chaves para o sucesso da mobilidade elétrica. Mas eles são sensíveis e precisam ser mantidos confortáveis em uma temperatura ideal para durarem muito tempo. É por isso que a minha chegada ao mercado em 2009 foi uma notícia tão boa: sou a primeira solução de refrigeração do mundo para baterias de lítio!

Minha estrutura é uma placa de resfriamento feita de alumínio. Existem canais dentro de mim através dos quais o refrigerante evapora. Isto mantém a temperatura do núcleo da célula dentro da faixa ideal. Fui instalado primeiro em um veículo híbrido.

Desde a minha estreia mundial, a MAHLE continuou a melhorar meu design. Atualmente, protejo baterias de muitos fabricantes de veículos em todo o mundo. E graças ao resfriamento por imersão, existe agora uma nova geração de sistemas de baterias que permitem que os veículos elétricos sejam carregados muito mais rapidamente sem causar danos às células. Com estes desenvolvimentos, a MAHLE demonstra a sua força inovadora na definição da mobilidade futura!

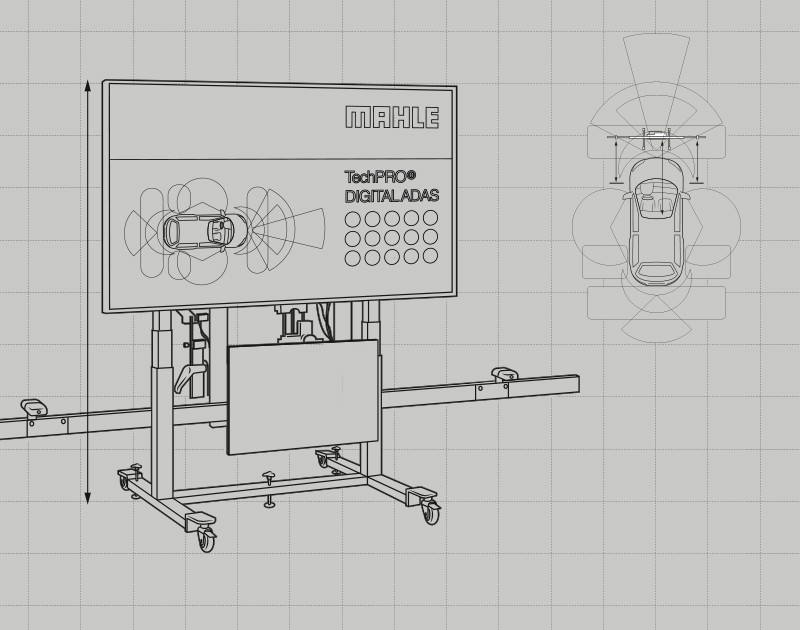

TechPRO® ADAS Digital

“Graças a mim, as oficinas podem respirar aliviadas”

“Estou sempre disponível durante a substituição de um para-brisas ou de outras peças de veículo onde estão montados importantes assistentes de condução. Hoje em dia, cada vez mais carros estão equipados com sensores e câmeras. Isto significa que as oficinas enfrentam um grande desafio quando se trata de reiniciar os sistemas de assistência de condução após um acidente, por exemplo.

Antes da MAHLE me inventar em 2018, os técnicos tinham que posicionar um painel grande e pesado na frente de cada carro – e havia um painel diferente para cada modelo de veículo. Esses painéis atuam como ópticos, ajudando a orientar os sistemas de assistência para que possam distinguir de cima para baixo e de trás para frente. Como resultado, a calibração costumava ser um processo complexo.

Quando eu, TechPRO® ADAS Digital, entrei em cena, oficinas em todo o mundo puderam finalmente respirar aliviadas! Combinei os painéis em um display digital de tela plana, que funciona para quase todos os fabricantes e modelos. Graças a mim, os técnicos da oficina podem calibrar os sistemas de assistência ao condutor em apenas dez minutos. O número de carros com sistemas de assistência ao condutor continuará a aumentar. Isso significa que estou em alta demanda – com clientes perguntando por mim todos os dias.”

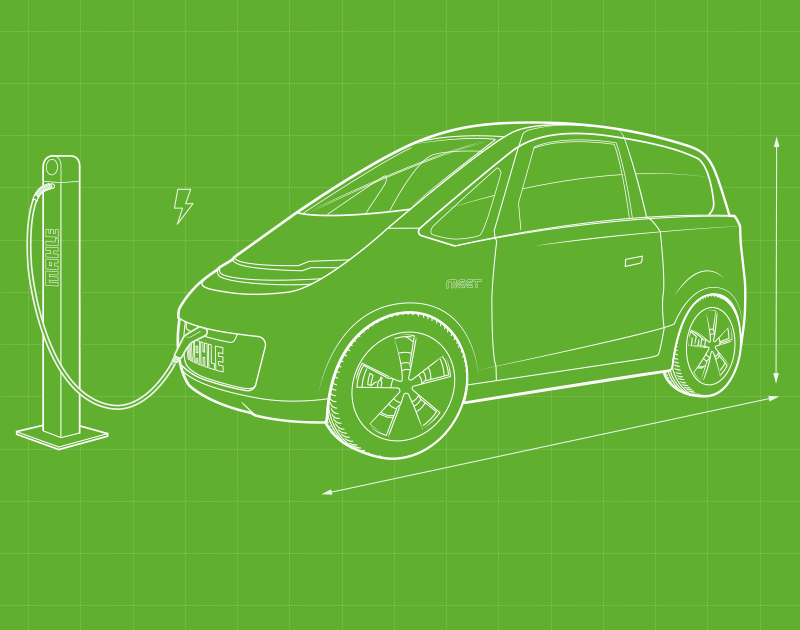

MAHLE MEET

“Mostro a força inovadora da MAHLE”

“No futuro, uma grande proporção da população mundial viverá em cidades. Isto significa que os automóveis urbanos serão um elemento importante da mobilidade futura. A MAHLE aproveitou esta oportunidade para desenvolver um conceito de mobilidade que seja ao mesmo tempo urbano e amigo do clima – eu!

Meu nome é MAHLE Efficient Electric Transport, meus amigos me chamam de MEET. Sou um conceito de veículo leve e ágil, com espaço para duas pessoas, e meu design integra trem de força MAHLE e tecnologias de gerenciamento térmico para mobilidade!

Desde os meus motores de acionamento de 48 volts até minha eletrônica de potência, bomba de água eficiente e aquecedores de superfície, até minha interface de usuário, apresento o portfólio abrangente e a força inovadora da MAHLE. Eu incorporo o compromisso da MAHLE de desempenhar um papel ativo na definição da mobilidade futura.”

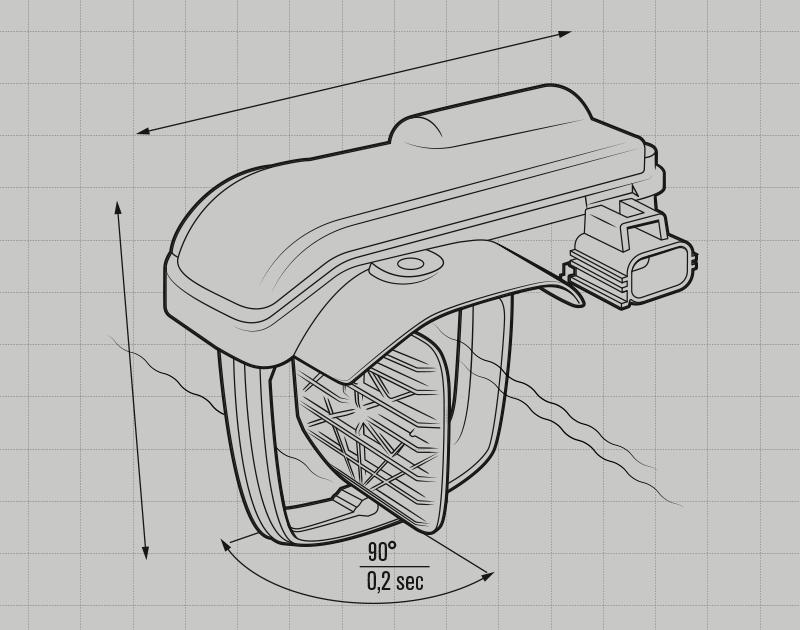

Atuador do tubo de admissão

“Todas as atividades mecatrônicas da MAHLE começaram comigo”

Na verdade, sou bastante simples – no entanto, inaugurei uma nova era na MAHLE. As atividades da MAHLE na área de mecatrônica começaram comigo, o atuador do tubo de admissão. Sou o primeiro produto nesta área que a própria MAHLE desenvolveu e produziu.

Certifico-me de que a coluna de ar na seção de admissão do motor ressoa na frequência certa e entra suavemente no cilindro. Minha caixa é leve e resistente e trabalho com muita precisão e rapidez: posso abrir 90 graus em 200 milissegundos.

Desde que entrei em produção em 2005, a MAHLE tem avançado constantemente no campo da mecatrônica. A nova unidade de negócios de Eletrônica e Mecatrônica foi criada no início de 2020. É aqui que a MAHLE reúne todas as suas atividades no segmento e desenvolve as tecnologias do futuro.

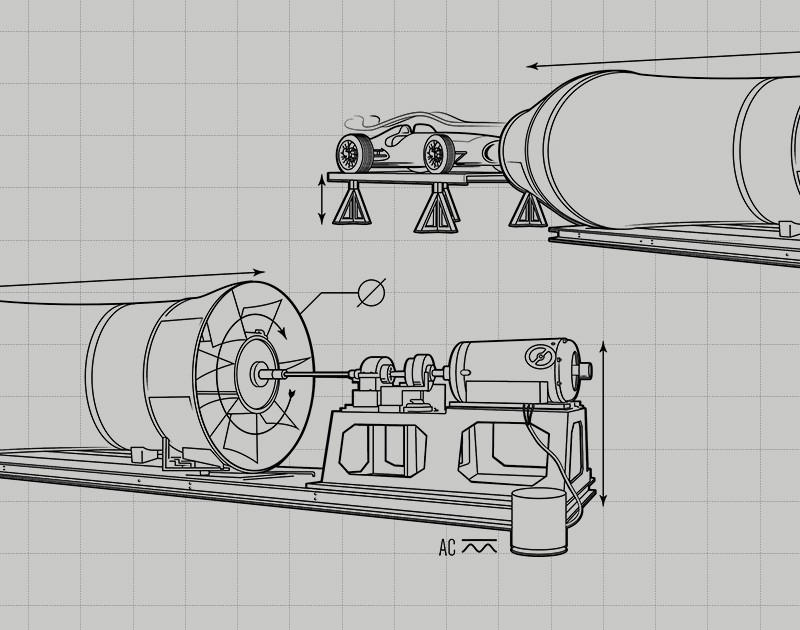

Túnel de Vento

“Fui o primeiro no mundo”

“Quando meu criador, Manfred Behr, me inventou em 1937, as pessoas provavelmente não me acharam atraente por fora, mas quando olharam para dentro, ficaram sem fôlego! Por fora, eu tinha a aparência de um modesto galpão de ferro corrugado, mas por dentro algo completamente novo estava acontecendo: eu era o primeiro no mundo – o primeiro túnel de vento em qualquer lugar na indústria automotiva.

Um enorme ventilador com 2 metros de diâmetro simulava velocidades de até 100 km/h. Meu sucesso foi tão inovador que até otimizei o carro de corrida mais famoso da minha época.

Ainda estou por aqui – e aprendi muito desde que comecei. Como túnel de vento climático da MAHLE, tenho criado temperaturas que variam de –30°C a +50°C desde a aquisição majoritária da BEHR (em 2013). Também posso simular a posição do sol a qualquer hora do dia e gerar velocidades de até 130 km/h, o que ajuda a MAHLE a desenvolver a mobilidade do futuro.”

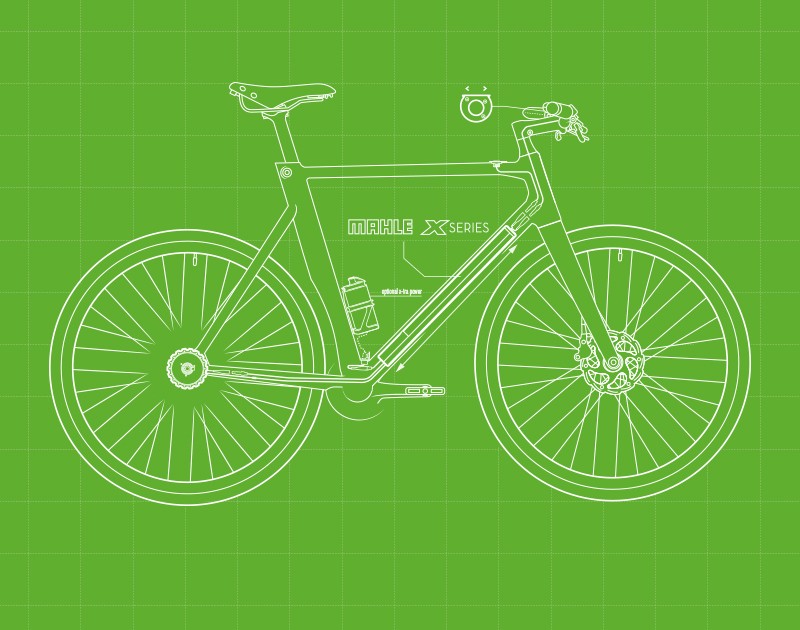

MAHLE X35

“Devolvi à bicicleta a sua identidade”

“As bicicletas elétricas são uma das maiores tendências na mobilidade atual – há cada vez mais delas nas ciclovias e trilhas de mountain bike do mundo. Mas graças à sua aparência, eles quase podem roubar a identidade da bicicleta. Isso ocorre porque baterias grandes não apenas tornam as bicicletas elétricas volumosas e pesadas, mas também alteram sua aparência externa. Então eu apareci – a MAHLE X35 – e devolvi a identidade à bicicleta!

É graças a mim que a e-bike é tão fina, elegante e esportiva – você dificilmente saberia que sou um sistema de direção. Ofereço aos usuários um ótimo nível de suporte. Afinal, como sempre digo, não é o máximo, mas sim o desempenho ideal que conta!

Com meu sistema compacto MAHLE X35+ atualizado, agora peso apenas 3,5 kg e forneço uma potência de 250 watts. Além do mais, também estou conectado digitalmente. Meu aplicativo exibe o pulso do ciclista ou quanto da minha energia elétrica está sendo usada. Você me encontrará em modelos vendidos por uma ampla gama de marcas internacionais de bicicletas elétricas bem conhecidas. Estou ajudando a MAHLE a desempenhar um papel ativo na formação da mobilidade sustentável!”

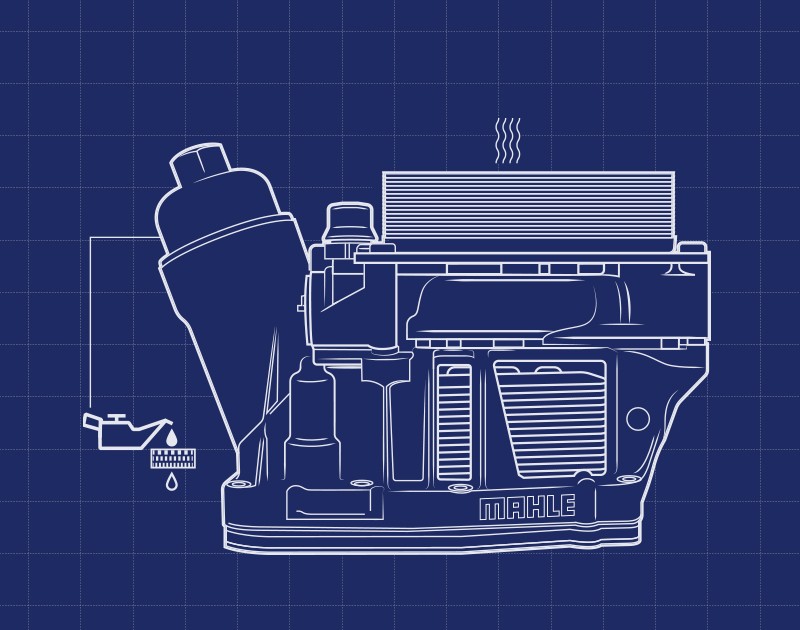

Módulo Filtro de Óleo

“Sou uma revolução na gestão do combustível”

A história de sucesso da MAHLE tem origem em pistões e filtros. Mas, em contraste com o seu negócio de pistões, a empresa interrompeu as suas atividades de filtros em 1941 devido à guerra. Então, em 1971, a MAHLE retornou nesta área de produtos ao adquirir uma participação significativa na Knecht Filterwerke.

Eu sou o módulo de filtros de óleo – um exemplo brilhante do trabalho contínuo de desenvolvimento e do impressionante know-how do segmento de negócios de filtros da MAHLE! Digo isso porque sou uma revolução na gestão do combustível. Tenho muitos talentos, mantendo o motor e o óleo da transmissão na faixa de temperatura certa, além de filtrar o óleo do motor, é claro. Mas ainda sou leve e compacto.

Iniciei no mercado em 2010 e posso ser instalado em praticamente qualquer carro – até mesmo em veículos híbridos. Demonstro a força inovadora da MAHLE no segmento de negócios de filtros!

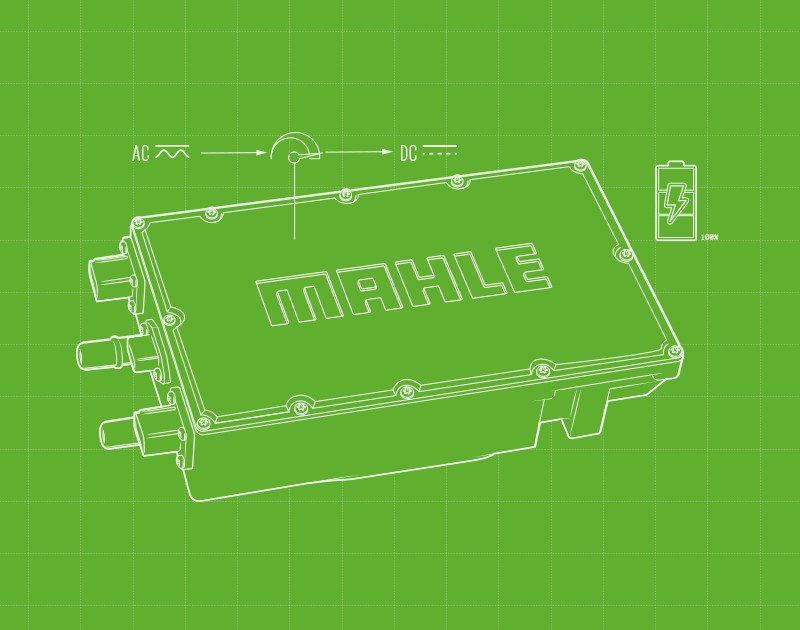

Onboard charger

“Carrego veículos elétricos rapidamente em qualquer lugar”

Para que a mobilidade elétrica se estabeleça nas nossas estradas a longo prazo, deve ser possível carregar veículos elétricos rapidamente e em qualquer local. Para que isso aconteça em qualquer lugar, a MAHLE me desenvolveu: o carregador de bordo.

Graças a mim, os veículos elétricos podem ser carregados em qualquer tomada. Isso porque eu transformo a corrente alternada em corrente contínua e gerencio o processo de carregamento. Ao fazer isso, ajudo a prolongar significativamente a vida útil da bateria. Como sou robusto e tenho um sistema de refrigeração inteligente, também facilito tempos de carregamento curtos em capacidades mais elevadas

.Ainda tenho muito mais a oferecer – e a MAHLE, uma força motriz ativa por trás da mobilidade futura, está preparada para desbloquear esse potencial. Por exemplo, poderei ajudar os carros elétricos não só a consumir energia, mas também a tornarem-se fornecedores de eletricidade através de uma bateria inteligente.

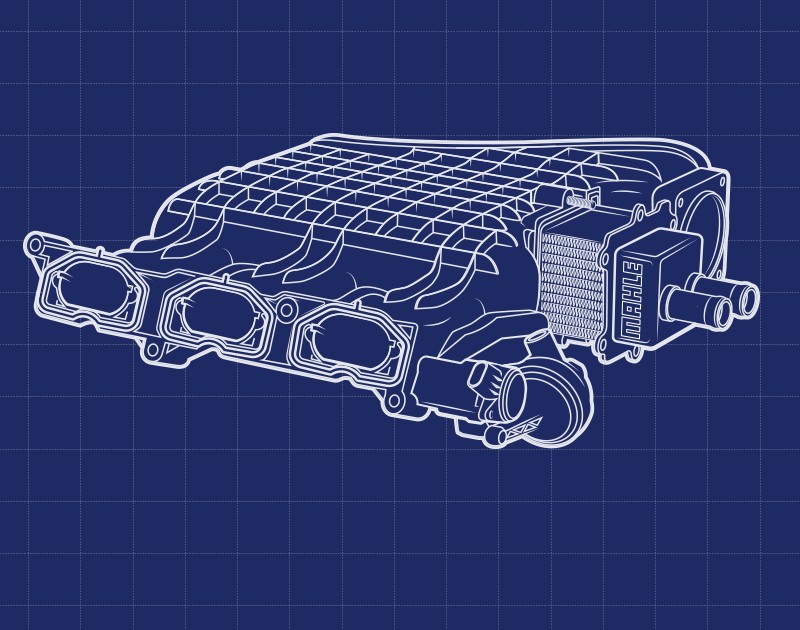

Módulo de admissão de ar com refrigeração indireta integrada

“Sou o resultado inovador de um excelente trabalho em equipe!”

Juntas, MAHLE e BEHR são maiores que a soma de suas partes! Fui o primeiro a provar a veracidade desta máxima. Em 2011, fui o primeiro projeto em que a MAHLE e a BEHR trabalharam juntas: o módulo de admissão de ar com refrigeração indireta integrada.

O que há de especial em mim é que meu refrigerador de ar de admissão – produzido pela BEHR – está integrado diretamente no tubo de admissão – produzido pela MAHLE. Isto significa que não só reduzo a perda de pressão e, portanto, aumento a eficiência, mas também crio mais espaço de instalação e aumento a capacidade de refrigeração.

Sou uma grande história de sucesso! Porque represento um importante passo no desenvolvimento de motores de combustão modernos, sou agora líder de mercado e estou instalado em veículos em todo o mundo. E, graças à experiência combinada da MAHLE e da BEHR, sou o resultado inovador de um excelente trabalho em equipe!

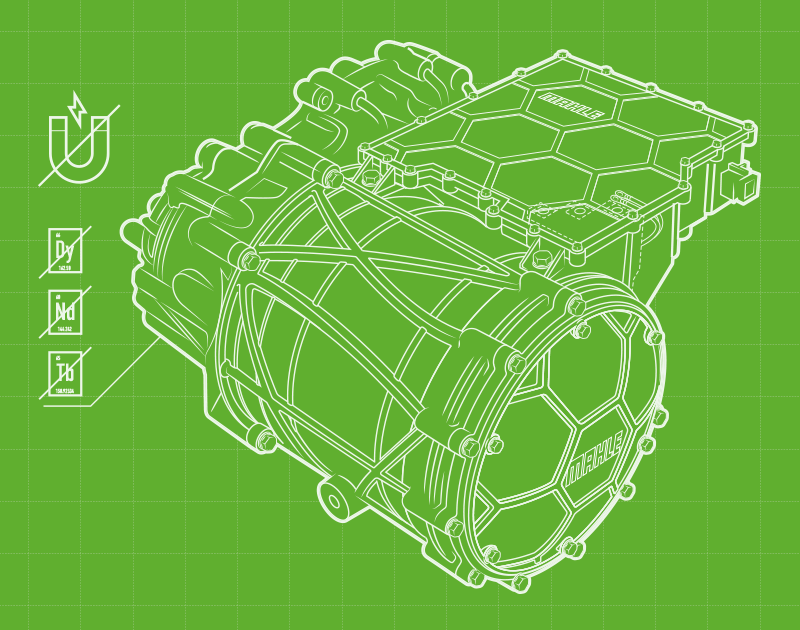

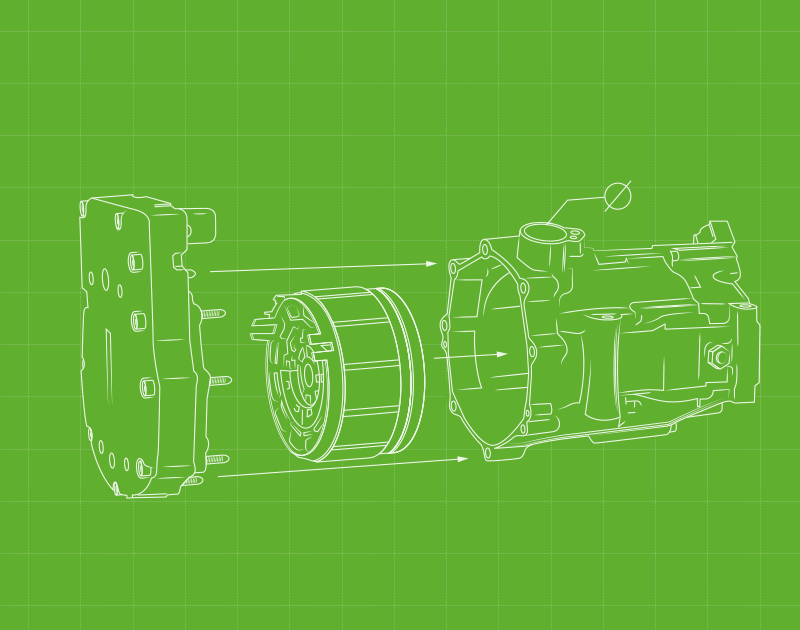

Motor de alta tensão sem ímã

“Não preciso de nenhum elemento de terras raras, por isso sou muito sustentável”

Os veículos elétricos serão uma parte importante da mobilidade futura. Porque precisam ser sustentáveis, adequados para o uso diário e econômicos, a MAHLE desenvolveu um conceito de propulsão que é ideal para uma ampla variedade de tipos de veículos elétricos – eu!

Sou o motor de alta tensão sem ímã e posso ser usado em qualquer veículo, desde subcompactos até comerciais. Sou particularmente conhecido pelo fato pelo desempenho sem ímãs. Isso me torna mais sustentável, porque não preciso de nenhum elemento de terras raras. Além disso, a forma como opero significa que a corrente elétrica é transmitida sem desgaste e sou eficiente na faixa de carga parcial.

Entrarei em produção de série muito breve e serei produzido pela nossa recém-criada unidade de negócios de Eletrônica e Mecatrônica. Estou ajudando a MAHLE a desempenhar um papel ativo na formação da mobilidade elétrica sustentável!

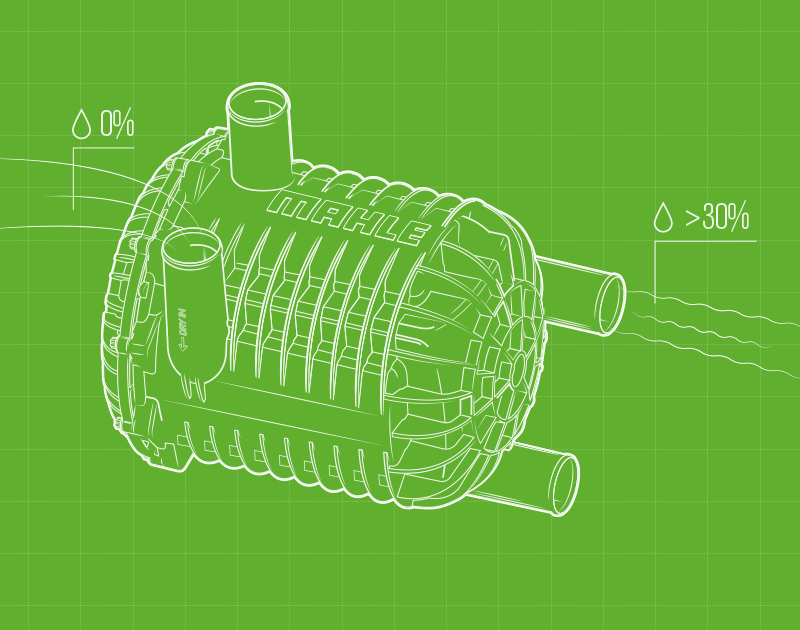

Umidificador de membrana para veículos com célula de combustível

“Sou um exemplo da grande força inovadora da MAHLE”

Fornecer ar a uma célula de combustível é extremamente desafiador. Isso porque, diferentemente de um motor a combustão, o ar também precisa estar úmido para que o sistema funcione de maneira suave e eficiente. Meu papel como umidificador de membrana plana é garantir que o teor de umidade do ar esteja correto – protegendo a célula de combustível contra danos!

Sou um exemplo da grande força inovadora da MAHLE. Sou compacto e de construção robusta e sempre mantenho o ar fornecido no nível ideal de umidade. Sou tão inovador que até recebo financiamento do Ministério Federal Alemão para Assuntos Econômicos e Energia (BMWi)!

A MAHLE tem trabalhado no meu desenvolvimento desde 2017, com tudo reunido no projeto da célula de combustível, e estou pronto para entrar em produção em série em 2023. Estou ajudando a MAHLE a desempenhar um papel ativo na formação de um trem de força chave do futuro!

Sistemas de Trem de Força

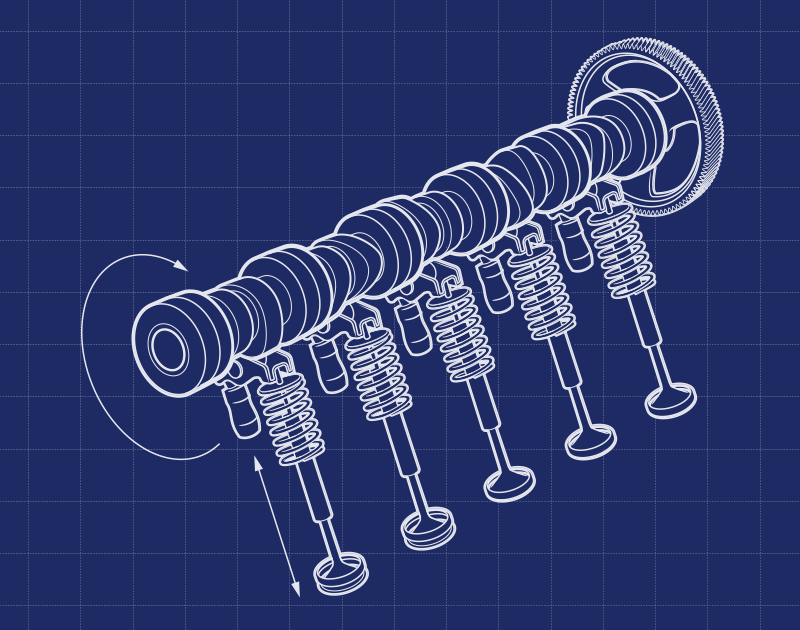

“Eu sou o pulmão do motor”

“Se você pensasse nos componentes de um motor como órgãos, então eu seria seus pulmões. Isso porque me certifico de que o motor respire a quantidade certa de ar fresco para o processo de combustão no momento certo e respire novamente o ar queimado.

Sou o trem de válvulas e tenho sido uma parte fundamental do portfólio da MAHLE desde a aquisição da Wizemann (em 1991) e da Pleuco (em 1994). Quando entrei na empresa, a MAHLE expandiu enormemente sua ampla base de conhecimento, abrangendo todos os aspectos do motor – e a equipe continuou me desenvolvendo.

Hoje em dia sou muito flexível e o meu timing perfeito permite-me ajudar os motores a reduzir as suas emissões poluentes, consumir menos combustível e, ainda assim, proporcionar um desempenho superior.”

E-Compressor

“Sou um produto chave para a mobilidade elétrica”

Para garantir a ampla aceitação da mobilidade elétrica entre os motoristas, os veículos elétricos precisam ser eficientes e fornecer uma autonomia de cruzeiro adequada para a sua área específica de aplicação. Felizmente, a MAHLE desenvolveu um produto chave justamente para esse desafio: eu, o compressor elétrico de ar condicionado!

Sou o coração do circuito de ar condicionado e forneço ar refrigerado para a cabine e para a bateria – com a minha ajuda, os veículos elétricos podem ser carregados rapidamente. Em outras palavras, grandes partes da bateria do veículo podem ser carregadas em apenas 15 minutos.

Sou tão sustentável que, em 2019, até ganhei o Prêmio Inovação CLEPA na categoria Ambiente, vencendo 63 concorrentes! Então, sou um grande sucesso, porque estou ajudando a MAHLE a melhorar a aceitação e o status da mobilidade elétrica no longo prazo.