| 2010 |

- MAHLE and Behr sign a participation contract and agree that the company shares will be transferred in several stages; in the first stage, MAHLE acquires 19.9 percent

- The MAHLE day-care center is opened near the group headquarters in Stuttgart/Germany

- Majority acquisition of the industrial business of the Behr Group (now MAHLE Industrial Thermal Systems GmbH & Co. KG)

- New filter plant opened in Tianjin/China

- New positive temperature coefficient (PTC) heaters for activated carbon canisters

- First use of modular all-plastic oil filter housing in the fields of commercial vehicles, industry, and generators

- Series production of all-plastic-oil filters with integrated thermal management

- First TopWeld® steel pistons for passenger car applications

- Development of a range extender (two-cylinder in-line engine)

|

| 2011 |

- Shareholding in the Behr Group increased to 36.85 percent

- Acquisition of remaining shares in the Turkish engine components manufacturer MAHLE Mopisan (now MAHLE Motor Parçalari San. ve Tic. A.Ş.)

- New filter plant in Chennai/India commences series production

- Ballast water treatment system for ships is certified; first high-volume order

- Development of cooling systems for gearless wind power plants

- Development of indirect charge air cooling integrated in the air intake module

|

| 2012 |

- Participation in the Tokyo-listed company Kokusan Denki Co., Ltd., a specialist for mechatronic products

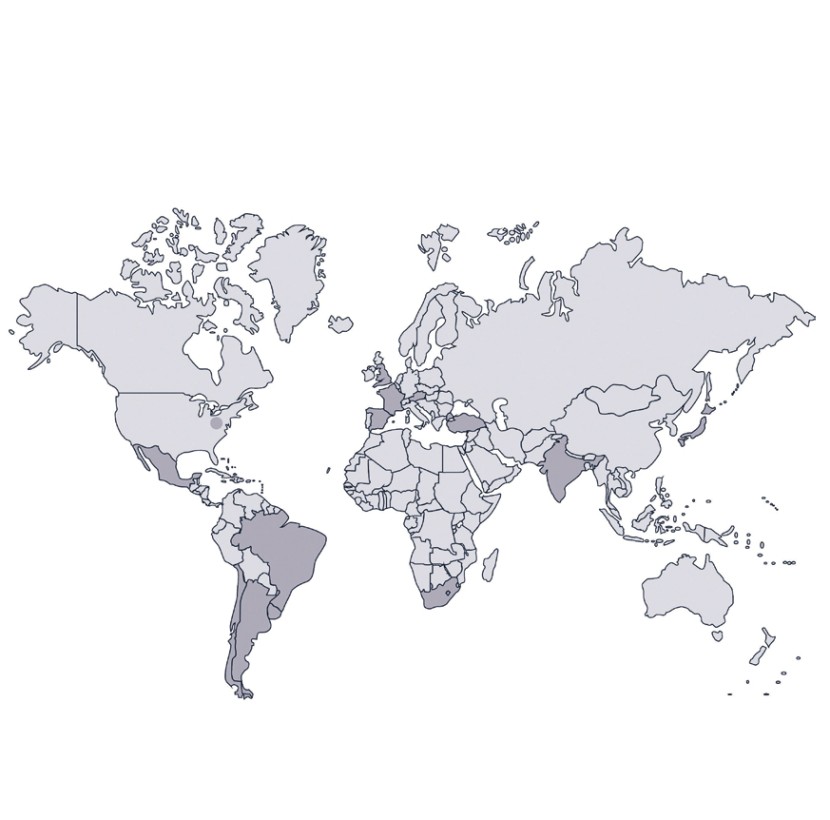

- Opening of the new Japan headquarters in Tokyo and the North America headquarters in Farmington Hills near Detroit/USA

- New filter plant opened in Kyushu/Japan

- Second expansion of the research and development center in Shanghai/China

- Expansion of the piston plant in Bangkok/Thailand and the filter plant in Samut Prakan/Thailand

- Development of MAHLE Jet Ignition—an innovative spark-ignition combustion process for extremely lean combustion

- New beam-based welding technology for heavy-duty steel pistons reaches process maturity

- Series production of assembled camshafts for commercial vehicles

- Development of cascaded charge air cooling integrated in the air intake module

- New oil filter module for commercial vehicles, integrating a coolant pump and thermostat as well as sensor technology for temperature control

- Development of energy-efficient actuation of engine accessories

- MAHLE range extender, a 0.9-liter two-cylinder in-line gasoline engine with integrated generator, installed in a demonstration vehicle

- Development of counterflow staggered blade charge air cooler for indirect charge air cooling of large engines

|

| 2013 |

- Shareholding in the Behr Group increased to 50.71 percent; MAHLE Behr forms the new Thermal Management business unit

- Expansion of the MAHLE Aftermarket logistics center in Schorndorf/Germany

- Opening of the new competence center for pumps in Brattendorf, Thuringia/Germany

- Acquisition of RTI Technologies, Inc. headquartered in York, Pennsylvania/USA (now MAHLE Aftermarket Inc.)

- Acquisition of all shares in the Indian piston joint venture MAHLE IPL Limited (now MAHLE Engine Components India Private Limited)

- Development of the lightweight valves EvoTherm® and TopTherm®

- Development of the EVOTEC®-SC piston with an additional cooling gallery

- Development of an active fuel prefilter for diesel engines for use around the world in a new generation of engines and powertrains

- Development of a hydraulically controlled coolant pump

- Development of a two-level cooling module

- Development of a high-voltage PTC auxiliary heater with integrated power electronics

- Series production of a new cooling plate for cooling the electrical energy storage device

|

| 2014 |

- Acquisition of majority share in Letrika in order to expand the mechatronics/electrics business (now MAHLE Electric Drives)

- Opening of two new distribution and logistics centers for the Aftermarket business unit in Limeira/Brazil and Obninsk/Russia

- Increased shareholding in the Japanese company Kokusan Denki Co., Ltd.

- Third expansion of the research and development center in Shanghai/China

- Opening of a new filter plant in Wuhan/China and a new plant for manufacturing automotive air conditioning and engine cooling products in Shenyang/China

- Bosch Mahle Turbo Systems founds subsidiary in China

- New filter plant opened in Cikarang near Jakarta/Indonesia

- Development of a downsizing natural gas engine and installation in a demonstration vehicle

- Series production of steel pistons for passenger car diesel engines

- Development of an oil cooler made of stainless steel for medium-sized and heavy-duty commercial vehicles

- Large-scale production gasoline engine equipped with a high- and low-pressure EGR system and installed in a demonstration vehicle

- Development of a systemic approach based on the Rankine cycle, which consists of an expansion machine, a feed pump, and various heat exchangers

- Development of an air intake module with integrated indirect charge air cooling

|

| 2015 |

- Acquisition of Amovis GmbH (now MAHLE Amovis GmbH)

- First fully automated production line for passenger car steel pistons in the world

- Takeover of the thermal management business of Delphi and integration into the MAHLE Group

- Opening of two new plants in Mexico: for the production of thermal management products in Ramos Arizpe and filtration products in Celaya

- Majority acquisition of the Japanese company Kokusan Denki Co., Ltd. (now MAHLE Electric Drives Japan)

- Opening of a new plant in Chengdu/China for producing air conditioners as well as components and systems for engine cooling

- Product launch of TechPRO®, a diagnostic tool for the aftermarket, on the US market

- Development of a monovalent natural gas (CNG) drive and installation in a demonstration vehicle

- New lean burn combustion process “MAHLE Jet Ignition®” is used in Formula 1

- Use of MAHLE electric motors in electric scooters

- Development of the particularly lightweight and structurally stable EVOLITE® piston and the EVOTEC® RSC piston with ring carrier and integrated cooling gallery

- Air conditioning compressors added to the air conditioning portfolio

- Battery temperature control using thermoelectric heat pump enters series production development

- MAHLE Foundation celebrates its 50th anniversary.

|

| 2016 |

- Sale of the industrial filtration business

- Merger of the electric drives and applications as well as the actuators product areas into the Mechatronics division

- Opening of the Vehicle Engineering Centre in Northampton/Great Britain in order to extend the range of products and services offered to automobile manufacturers in the field of future-oriented powertrain technologies

- Opening of a new testing center in Plymouth, Michigan/USA

- MAHLE signs the Diversity Charter

- Start of the ACTIVATR innovation program

- World’s first controllable pendulum-slider oil pump for commercial vehicles

- World premiere of the CareMetix® cabin filter, which protects against solid matter and gas particles and eliminates odors

- Development of the world’s first map-controlled thermostat for commercial vehicle applications

- World’s first R744 air conditioning system in series

|

| 2017 |

- Mechatronics division expanded to include the control and power electronics product group.

- Locations in Stuttgart/Germany receive seal of approval for their family-friendly personnel policy

- Start of the internal innovation program “Incubator”

- Collaboration with Faurecia on technologies for thermal management in the Cockpit of the Future

- Sale of the forging activities and therefore of the plants in Plettenberg and Roßwein, both in Germany

- Acquisition of the start-up O-Flexx Technologies GmbH, allowing entry into the thermoelectrics market (now MAHLE Thermoelektronik GmbH)

- Acquisition of the Spanish electronics specialist Nagares SA (now MAHLE Electronics S.L.U.)

- Acquisition of minority holding in BRAIN BEE® AG, a specialist in automotive workshop equipment

- Construction of a new plant in Krotoszyn/Poland

- Sale of shares in the Brazilian components manufacturer MAHLE Metal Leve Miba Sinterizados

- Opening of a new plant for air conditioning compressors in Changshu/China

- World debut of 48-volt vehicle concept “MEET” (MAHLE Efficient Electric Transport) at IAA Cars in Frankfurt/Germany

- Pedelec drives in series production

- Development of a new liquid management module combining an electric coolant pump and cooling circuit control for CO2 reduction

- Development of e-compressors for different power classes

|

| 2018 |

- Shareholding in the Behr Group increased to 55.71 percent

- Sale of the 50/50 joint venture Bosch Mahle Turbo Systems GmbH & Co. KG by mutual agreement with the Bosch Group

- Sale of the shares in Hella Behr Plastic Omnium (HBPO)

- Acquisition of ebikemotion® Technologies SL, a specialist in pedelec systems, HMI, and connectivity (now MAHLE Ebikemotion S.L.U.)

- Opening of a new research and development center for electronics in Valencia/Spain

- Opening of a new WLTP- and RDE-capable testing and certification center (RDEC) in Northampton/Great Britain

- Majority acquisition of BRAIN BEE® (now MAHLE Aftermarket Italy)

- Opening of the first production line for electric air conditioning compressors in Balassagyarmat/Hungary

- Systems solutions for hybridization in the field of commercial vehicles (thermal management, drive motors, and power electronics)

- Development of e-waste heat recovery system for commercial vehicles in a compact box

- Development of a new oil management module for vehicles with electric drive systems

- Demonstration of an innovative valve train system for commercial vehicles that integrates functions such as engine braking or exhaust gas temperature management into the valve train (Shifting Roller System)

- Demonstration of a flat membrane humidifier for reliable humidification of supplied air, optimizing the efficiency and service life of a fuel cell

- Production-ready solutions for the temperature control of batteries, electronics, and electric motors as well as solutions for monitoring the fuel cell stack

|

| 2019 |

- Shareholding in the Behr Group increased to 60.71 percent

- Acquisition of the transmission specialist ZG-Zahnräder to expand MAHLE’s competence for the powertrain

- Entry into wireless charging of electric vehicles

- MAHLE corporate start-up chargeBIG secures order from Stuttgart Airport for a charging system for electric vehicles

- New production process allows steel pistons to be used in powerful passenger car engines

- Materials and components from MAHLE are ready for synthetic fuels

- MAHLE combines its development areas in a fuel cell project house

- With its power electronics, traction motors, and charging infrastructure solutions, MAHLE offers a broad range of products for e-mobility

- MAHLE expands its range of components for e-bikes

- Integrated heat-pump-based system from MAHLE reduces cruising range loss for electric vehicles by up to 20 percent

- Market launch of the diagnostic tool TechPRO®

|

| 2020 |

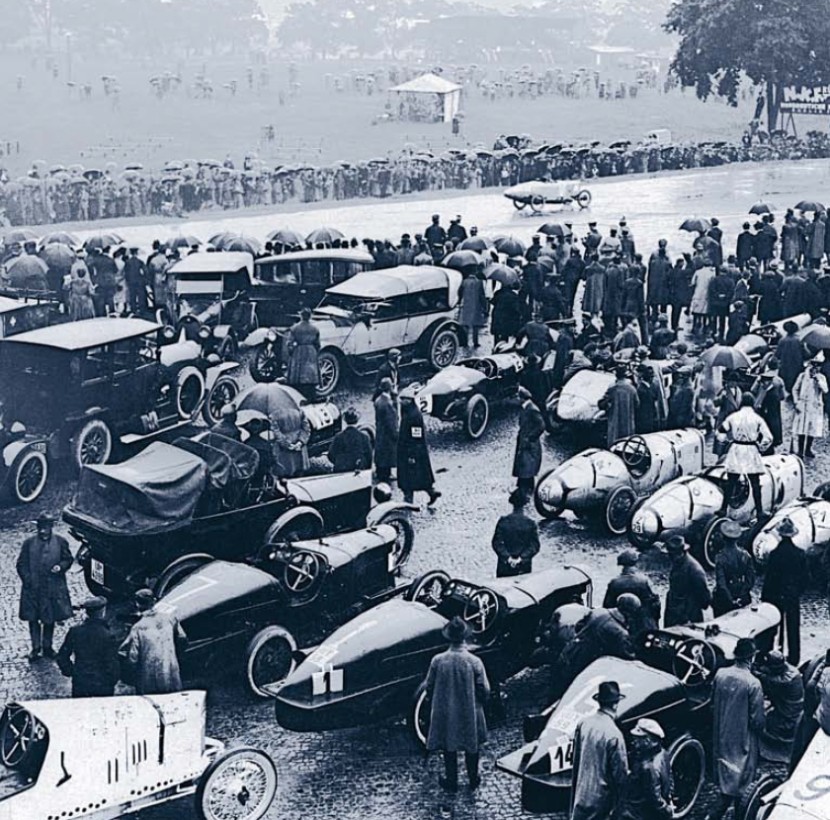

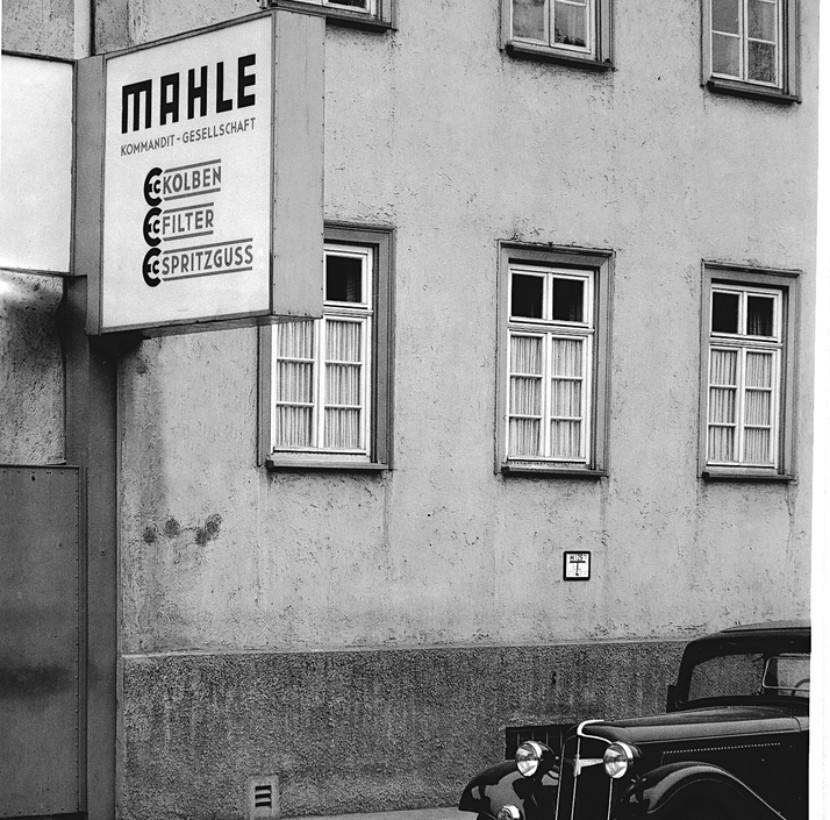

- MAHLE celebrates its 100-year anniversary

- Establishment of the new Electronics and Mechatronics business unit

- Acquisition of all shares in Behr Hella Service (BHS), expanding the thermal management portfolio in the Aftermarket business unit for conventional and electrically powered vehicles

- New production, research, and development center for workshop equipment opened in Parma/Italy

|