100 años de espíritu de desarrollo

MAHLE has been keeping people in motion for 100 years

Es el año 1920. La loca década de 1920 apenas comienza. Es el comienzo de una década apasionante en la que Charles Lindbergh cruzará el Atlántico, Albert Einstein recibirá el Premio Nobel, Mahatma Gandhi iniciará su protesta no violenta, se fundará Deutsche Luft Hansa AG y se inaugurará Nürburgring. Y en Bad Cannstatt / Alemania, se están sentando las bases para una empresa global: en las próximas décadas, Ernst y Hermann Mahle desarrollarán productos que se convertirán en los más vendidos y establecerán la reputación de la empresa global actual como innovadora.

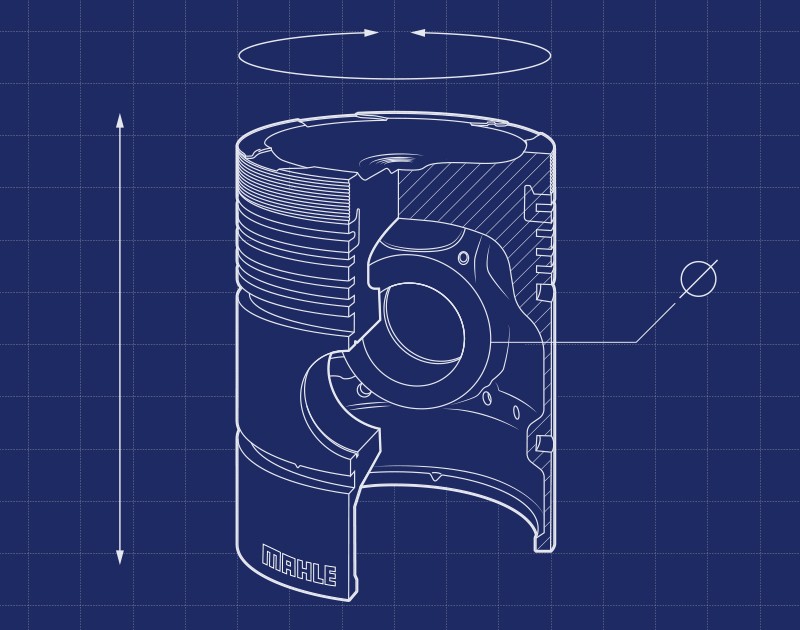

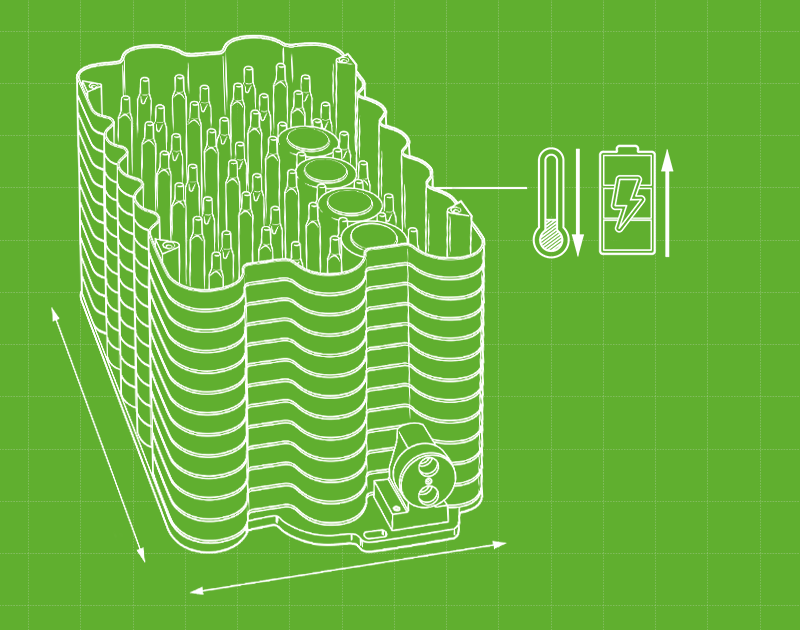

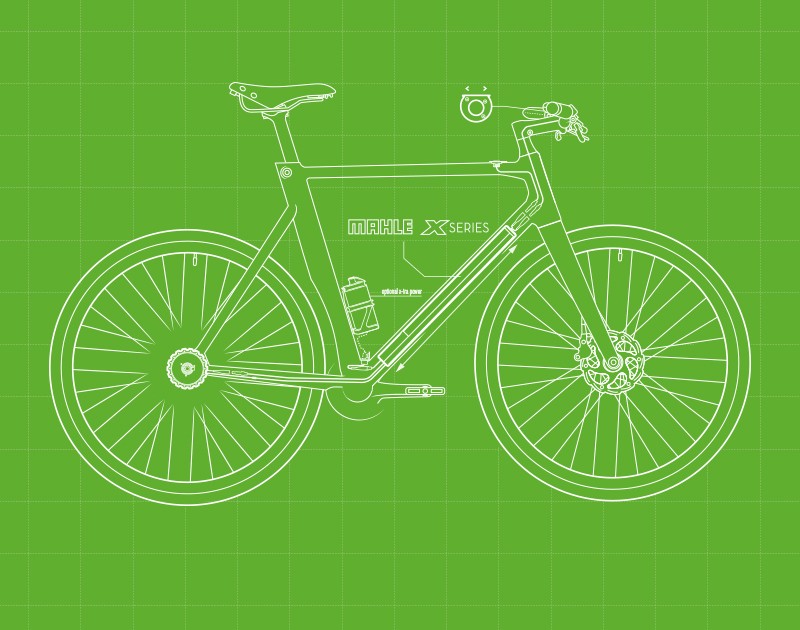

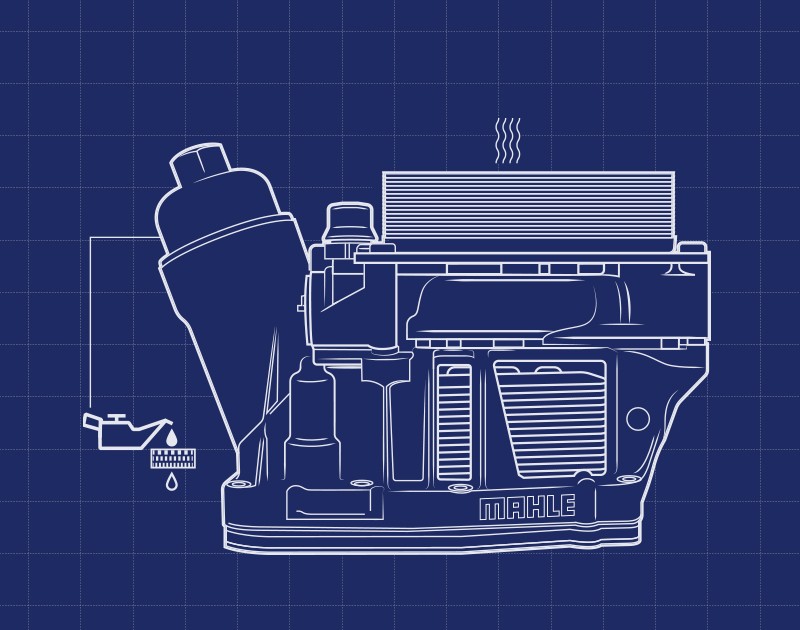

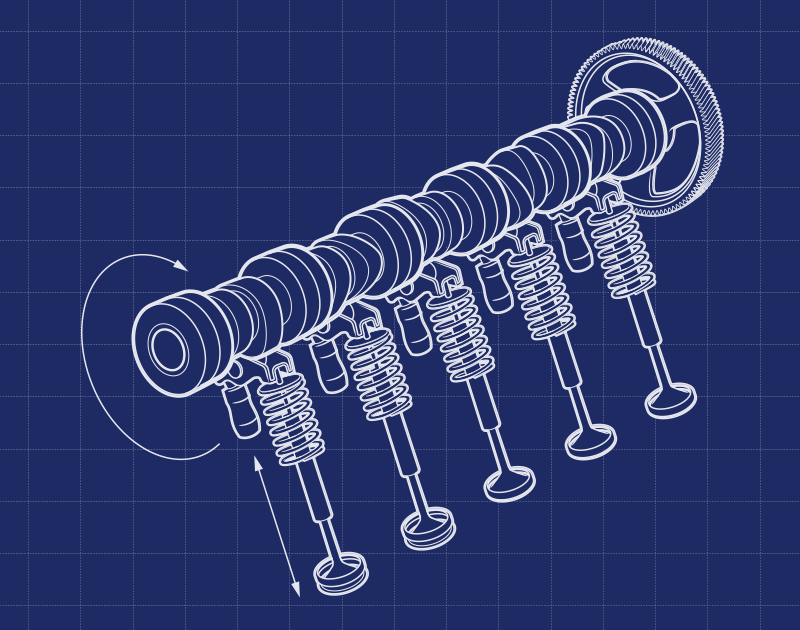

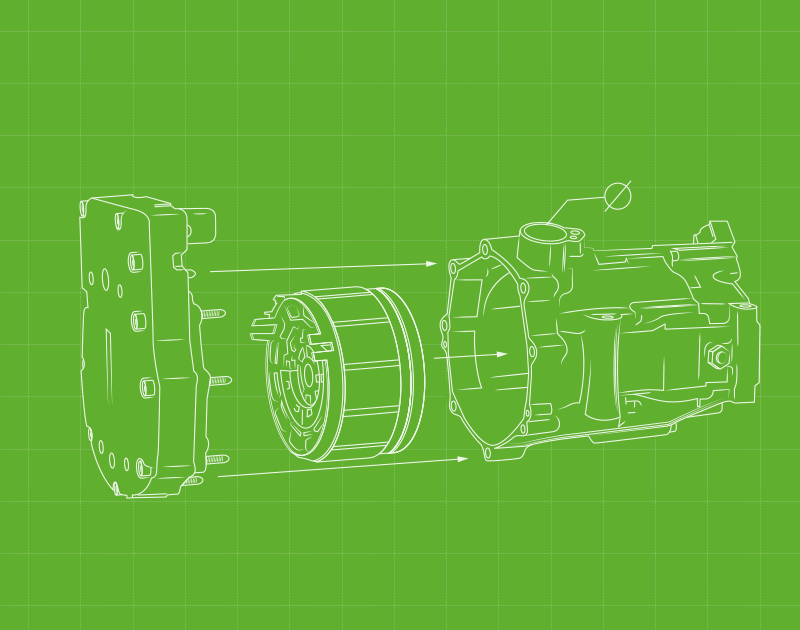

Desde entonces, MAHLE se ha convertido en uno de los 20 proveedores automotrices más grandes del mundo, con alrededor de 72.000 empleados. Hoy somos pioneros en la movilidad eficiente del mañana. Nuestras soluciones innovadoras continúan estableciendo nuevos estándares en el campo de los accionamientos alternativos y en la optimización de motores de combustión interna.

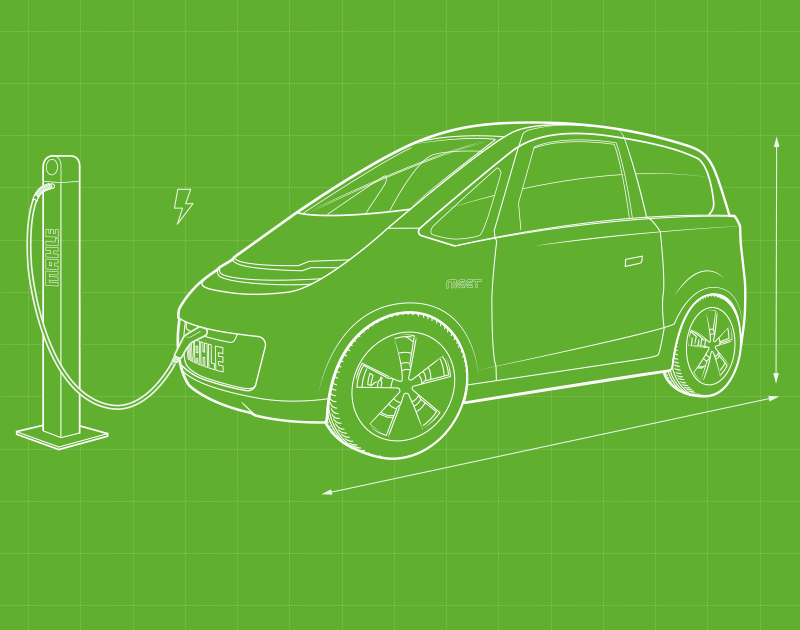

Cual es nuestra motivacion? Queremos que la gente vaya de A a B de manera eficiente y cómoda. Junto a la industria, la política y la sociedad trabajamos los grandes retos de nuestro tiempo, siempre atentos a ellos. Somos los creadores de la movilidad individual sostenible. Además, como parte de la fundación MAHLE, asumimos la responsabilidad social.

Hoy y mañana. Para las generaciones futuras. Y durante los próximos 100 años.

MAHLE Greatest Hits

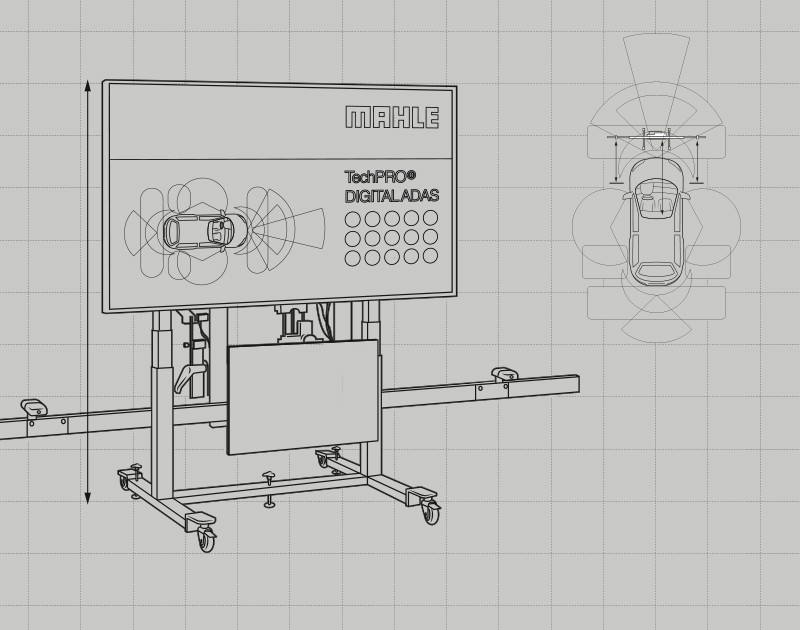

MAHLE has been shaping mobility for 100 years. In the MAHLE Greatest Hits series, MAHLE’s most acclaimed innovations of the past and present tell their own tales of how they promoted mobility. Then we will also take a glimpse into the future, how upcoming MAHLE innovations will contribute in our quest to shape the future of mobility.